3.5㎡Big Curing Area

2.05*1.75m covered drying area. It can cure doors, fenders, bumpers, trunk, short hood directly, or other panels on stand...

70% Energy-savings

Compared with the electric IR Dryer system, energy savings of catalytic dryer is up to 70%, and the emissions are only water vapor and carbon dioxide.

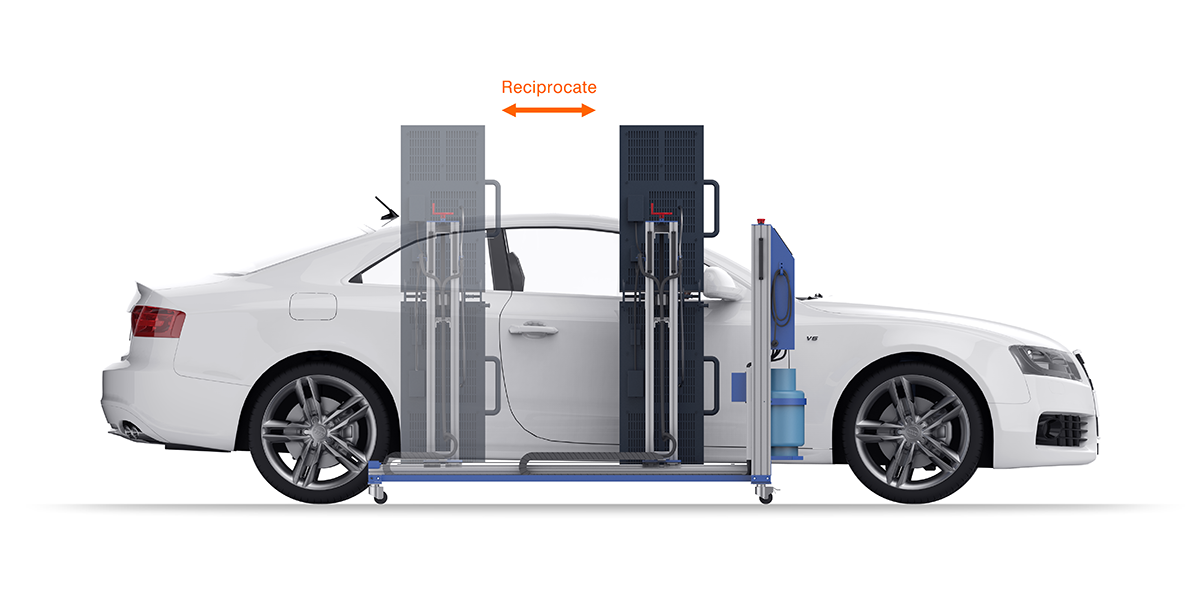

Flexible movement

It can be pulled to Prep station, paint booth, spray booth...no restrictions on the using location, no necessary to move cars!

Mitsubishi PLC automatic control system

Automatic moving, multi program system for body filler, primer, color coat and clear coat drying.

No flame

The specially designed catalytic panel gets hot but there are no flame. When working, the surface temperature of emitting panel is 370-430℃, which is much lower than the ignition point of gas at 650℃. Perfectly safe to use.

Input Voltage: 220V(50/60Hz)

Single panel preheating power: 2Kw

Total output power:22Kw

Single panel output power: 11Kw

Single Panel LPG consumption: 0.65Kg/h

Single Panel natural gas consumption: 1.1m³/h

Minimum height of panel from the ground:140mm

Drying moving stroke:1500mm

Drying Area: 2050mm×1750mm

Panel height adjustment range:300mm